|

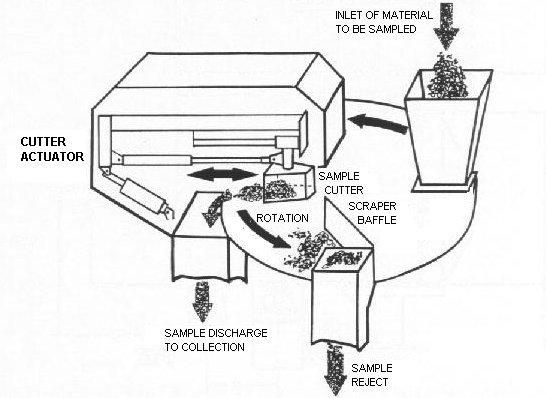

PFS ROTARY TABLE SAMPLER FOR SOLIDS SAMPLING |

|

|

The number following the PFS sampler model designation indicates table diameter (mm). |

|

|

The ROTARY TABLE SAMPLER enables efficient sampling of powders and solid materials including moist concentrates and other material having tendencies toward sticking to chute surfaces when using trajectory or top-belt sampling. The rotary table method also is efficient for sampling fine powders by avoiding sample bias resulting from fines classification occurring with gravity flow sampling. It is used for secondary or tertiary sampling, or for primary sampling of relatively small flows. The ROTARY TABLE SAMPLER operates by feeding material from a supply bin fitted with a gate to form a continuous mound of material to be sampled. Material flows from the bin in a circular path as the table rotates under the bin to draw material out. Representative samples of material are taken from this mound with a sample extractor (electrical or pneumatic actuators may be selected). The table rotation is effected by a gearmotor drive through a tooth belt pulley system for table operation typically in the range of 0.5 to 5 RPM. The adjustable height bin gate enables a constant rate flow of material feed from the bin onto the rotating plate. The moving mound of material being processed is retained within a specified band width by aprons positioned above the plate. Remaining solids (reject) after sample extraction are pushed off the plate by a fixed discharge baffle as the mound continues in rotation on the plate. Periodic extraction of sample increments from the flow are taken by cutter mechanical action as it is pushed down to the table surface through the mound until the cutter blades reach the table surface. Cutter retraction then removes the increment from the plate into a sample receiver. Cutter operation is sequenced by an electric timer. Table rotation is stopped for a few seconds each time a sample increment is extracted. The cutter is made with sides radial to the center of table rotation so to maintain theoretical rotary sampling technique for through-stream extraction. The method assures accurate representation of the process stream in extracted samples. The ROTARY TABLE SAMPLER concept combines uniform feeding of solids with requirement for minimum elevation to install the sampler. A linear sampling configuration by this concept can also be provided using a continuous flat belt feeder. A timer-starter control unit Model PB-200 series is available for operation of a single sampler, or alternatively operation can be carried out with a centralized control system. |

|

[Home] [Company Info] [Products] [Installations] [Theory] [Analyzers] [Contact Us] |

|

© 1997, Harrison R. Cooper Systems, All Rights Reserved |